WIKA PRODUCT LINE (FORMERLY PAT HIRSCHMANN)

WIKA Mobile Control is a leading manufacturer of control systems and load moment indicators and sensors for mobile equipment. Marketed under the brand names of Hirschmann, PAT, and Kruger, Hirschmann MCS has an extensive product portfolio that includes consoles, systems, and sensors that meet the requirements for OEM and retrofit mobile equipment applications. These electronic systems are used by building machinery manufacturers and end users in the fields of conveying, lifting and transport.

qSCALE MAESTRO

|

qScale Maestro

|

|

PAT DS 150

|

LMI for Smaller Hydraulic Boom Cranes

|

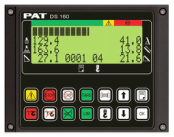

PAT DS160

|

LMI for Average Hydraulic Boom Cranes

|

PAT DS350

|

LMI for Larger Hydraulic Boom Cranes

|

PAT EI65

|

Geometry plus Load System

|

iFLEX 5

|

iFLEX 5

The iFLEX5 provides OEM’s and system integrators a powerful and scalable platform for systems management and operational control. The iFLEX5 supports a distributed systems approach with CanBus communications between all sensors and subsystems. Hirschmann takes an interactive approach to man-machine interface by collecting inputs from operator controls such as Hall effect joysticks and precision sensors, including pressure, speed and position. |

Hirschmann Maestro

|

Hirschmann Maestro

|

Hirschmann Mentor

|

Hirschmann Mentor

The Hirschmann mentor provides the operator with a continuous display of the crane’s actual and allowable load, boom length, boom angle, and load radius. The system also includes an integrated bar graph which displays the cranes utilization. The combination of the central unit being integrated into the console and the use of CAN Bus sensors provides for quick and easy installation. |

PAT PRS 90

|

PRS90 Wireless Multi-Sensor Indicator

The PRS90‘s flexible design allows for monitoring single or multiple sensors. The sensor inputs are displayed on a color graphic display which is capable of monitoring and displaying the status of up to eight sensors at one time. |

Downloads

Operator's Manual |

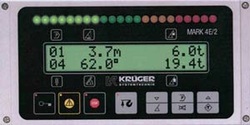

PAT MARK 4E/2

|

PAT MARK 4E/2

The MARK 4E/2 system operates on the principle of reference/real comparison. The real value, resulting from the load measurement is compared with the reference and calibration data, stored in the central processor memory and evaluated in the micro-processor. When limits are reached, an overload warning signal is generated at the indicator panel/ operator’s console. At the same time, the aggravating crane movements, such as hoist up and boom down, will be stopped. |

MANATEX PAT DS85

|

MANATEX PAT DS85

The PAT Load Moment Indicator1 (LMI) has been designed to provide the crane operator with the essential information required to operate the machine within its design parameters. Using different sensing devices, the Load Moment Indicator monitors various crane functions and provides the operator with a continuous reading of the crane’s capacity. The readings continuously change as the crane moves through the motions needed to make the lift. The LMI provides the operator with information regarding the length and angle of the boom, working radius, rated load and the total calculated weight being lifted by the crane. |